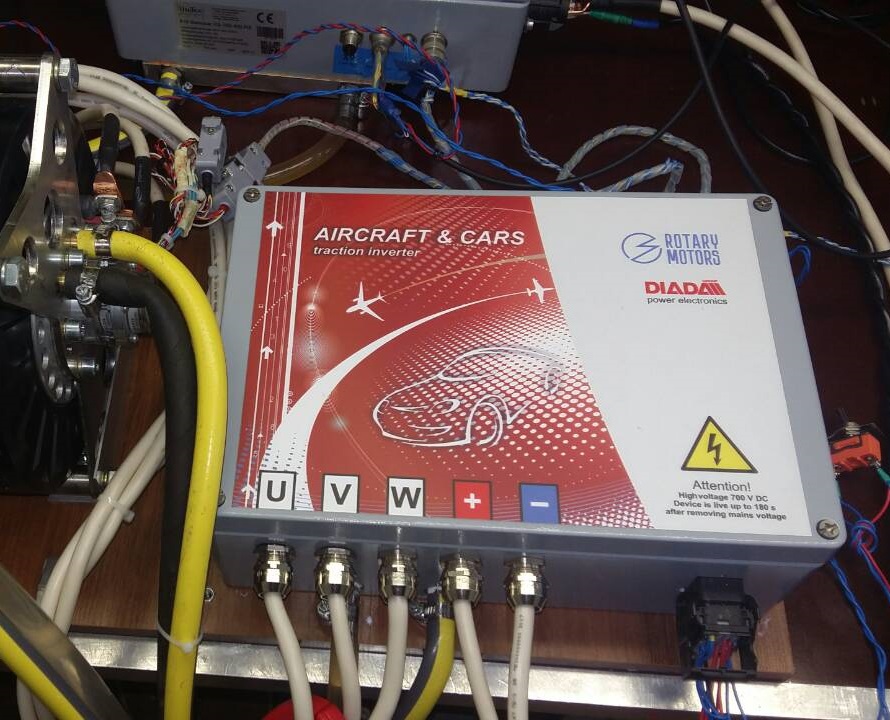

The EC-150 traction inverter

The "EC-150" traction inverter for transport applications.

The EC-150 benefits:

- Wide range of applications. By using the EC-150 it is possible to control both synchronous (PMSM, BLDC) and asynchronous 3-phase electric motors;

- Various methods for determining the position of an electric motor`s rotor. In the EC-150, there are possibilities for use both sensorless field-oriented control (FOC) and the use of Hall-effect sensors, encoders and resolvers.

- Multiple protection levels. In the EC-150, the power section is separated from the control unit and a safe shutdown is realized in the event of a short circuit, as well as in other unfavorable electrical conditions or overheating.

- Effective cooling. To cool the power components, liquid cooling is used, which ensures the best cooling of the traction inverter under continuous loads.

The EC-150 specifications:

|

Parameter |

Value |

Units |

|

Peak power (up to 10 seconds)) |

300 |

kW |

|

Rated power |

150 |

kW |

|

Peak voltage |

700 |

V |

|

Rated voltage |

600 |

V |

|

Peak current |

400 |

А |

|

Rated current |

200 |

А |

|

Switching frequency |

12 |

kHz |

|

Weight |

7,8 |

kg |

|

Dimensions (LхWхH) |

330х260х110 |

mm |

According to the the customer`s technical requirements, it is possible to change the parameters and/or to adapt the inverter to a specific vehicle.

Examples of usage:

The "Emrax 228" electric motor (peak power 100 kW) is controlled by the "EC-150" traction inverter. No sensors are used to control the motor (sensorless field-oriented control (FOC) is used).

Demonstration of the Emrax electric motor wich drives the VW/Audi transmission. The electric motor is controlled by the Bamocar D3 traction inverter. An expensive resolver is used to determine the position of the electric motor`s rotor.

To request detailed information please, use the Feedback Form, or call: (044)223-2709 or (094)823-2709.