Article:Locomotive of modern economy or car for sheikh

Economic might is the foundation of prosperity of the state and its tenable shield. It is clear now - there is no alternative for accelerated development of the economy through the introduction of innovative technologies. The rational using of all resources in order to improve the living standards of the people is the motto of the modern market economy. Only the richest states now (the government whom believes that its people are prospering) can afford the direct costs for retrofit of arming. As a rule, expensive weapons stored for many years at Arsenals, become out of date and then are recycled. All these enormous costs are discarding by the Ministry of Defence, from which there is no use in peacetime. But experts known other alternative way - a "dual use" for industrial product - in order to strengthen both economic and defense power of the state at once, with constant using of industrial products throughout their life cycle (i.e., without the useless storage in stockpiles) . On the possibility and feasibility of such a course will be discussed further.

1. Transport is the locomotive of the economy of developed countries

It is well known expression that says: "The car has created America". It is really true, because economists believe that one workplace in the automotive industry creates seven additional jobs in related industries. It is assumed that one workplace in the more high-tech aerospace industry creates even 12 - 15 additional jobs in other economic sectors of the country. That is why the level of development of the automotive, aerospace and shipbuilding industry serves as a criterion of status for the national economies. According to situation in these three industries, all of which are purely transport, it is possible to judge about the economic and military power of each state.

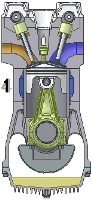

Technical and operational capacities of individual vehicles and the whole image of a modern transport are mainly determined by the type of applicable engines. The basis of modern transportation is Internal Combustion Engines (ICE) - the piston engines (with a capacity of up to 500 - 700 kW) in road transport and gas turbines (with a capacity of over 700 kW) in the aircraft and shipbuilding. I.e. today we have two monopolists in the propulsion engineering - piston engines occupy the bottom rung of the power and gas turbines occupy the top rung. The impartial judge of the rung power distribution this two types of motors is the cost-effectiveness.

If the applicability of gas turbine engines, which are absolute champions in power, is all clear until this time, the piston engines are obviously outside of the development of modern technological progress. Such a statement has an objective basis, so let's try to deal with the prospect for reciprocating internal combustion engines.

2. Crisis of piston engines

The "Gazmotoren factories Deutz", the company of August Nikolaus Otto, received in 1877 patent (№ 532) on the engine of a new design - single-cylinder, horizontal, which is working with four-stroke cycle. But very soon it became clear that the single-cylinder engines have a very uneven torque and for this reason they are not very fitted for practical use. The practical solution to this problem was simple - piston engines began to make a multi-cylinder with sequential shift in time passing of working processes in separate cylinders. Naturally, the design of such engines has become more complicated and more expensive, but the goal was achieved - the piston engine becomes suitable for practical applications, including transport. In fact, modern piston engine constitutes a few "bad" one-cylinder engines, which are combined into a single unit for the practical application by the lump. Otherwise, there are no any good results. Consequently, the presence of several cylinders in the design of modern reciprocating internal combustion engines is an objective fact of their imperfections. We have to put up with this fact so far, even 150 years after the invention which was done by N.Otto.

The piston engine design has not changed over the last 50 years. Typically, when people talk about the new engine, primarily have in mind some particular "attached deadlights" on an old and well-proven design of engines. Therefore we can say about the long-term crisis in the advancement of design of reciprocating internal combustion engines.

Disadvantages of modern piston engines inspire an army of inventors to work to eliminate them. Each specialist intuitively understands the benefits of a rotary kinematics before reciprocating movement of piston in a cylinder.

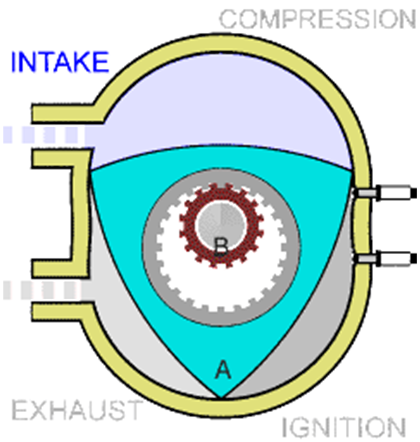

Despite numerous inventions in the field of engine development, a real alternative to the piston engines appeared only in 1957 after the development by the engineers Walter Freud and Felix Wankel (German company NSU) rotary-piston engines (RPE). In this engine all the kinematic elements of the engine are rotate uniformly (at constant external load) without the inertial accelerations due to the absence of reciprocating movement. These engines were even set previously in the serial cars, in particular cars of brand Mazda with the letters RE in the name (the first letters of the name «Renesis»). However, despite the promising performance of RPE, on set of technical, economic and environmental parameters they conceded a piston engines, first of all regarding a running time. There are no firms which equip their cars by the rotary-piston engines at present time.

And now inventors constantly offer new designs of engines. Unfortunately, as a rule, the constructive innovations in the proposed new engines have various drawbacks of fundamental nature which do not allow them to compete with the piston engines. Because 150 years of development and improvement of piston engines is their huge head start.

3. Innovations in the modern propulsion engineering

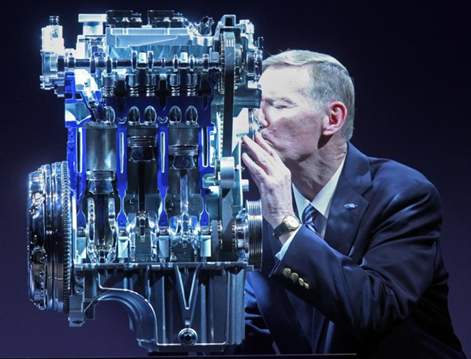

There are announcing every year the achievements of modern automobile industry and new engines for cars. There are constantly put into practice improvements of efficiency and environmental safety of ICE. As result this decreases the engines capacity, but increases their power. What is this - a paradox? There is no paradox here, for the simple reason that the improvement of parameters of the power plant for car (but not just only one piston engine) is achieved by purely rotary machines - due to turbochargers which powered by the exhaust gas, mechanical or electrical drive. It's simple. The air enters into piston engine not at atmospheric pressure as before, but with a supercharged 1.5 - 2 or even 3 of the atmosphere. The engine power increases accordingly to the air pressure at the inlet. The design of piston engine does not changing essentially if turbocharger is use. Professionals are well aware that turbo charging is almost the only one tool that somehow represents progress in the automotive engine industry. But the cost of engines and cars is not decreasing from this, but only growing, unfortunately.

A clear illustration for the told above is the engine of the family "EcoBoost" by the "Ford" company which is the winner in 2012 (see Fig. 1). This three-cylinder, turbocharged engine has a working volume of 999 cc and power of 125 hp. Block diagram of this internal combustion engine is shown at Fig. 2. It clearly reflects the tricks of developers with all kinds of turbochargers. Of course, car has not become cheaper with such engine. What's new in the design of the piston engine? Yes, almost nothing. It is done only with one cylinder less. Obviously, its developers want to somehow neutralize the evident drawback of reciprocating internal combustion engines in the form of a plurality of cylinders.

About the other monopolist, but only in aviation - gas turbine engines (GTE) - we can to say that it is this remarkable heat engine which in one unit combines together the engine and mover - the jet nozzle. Today, the "large" aircraft has no alternative engines - only gas turbines. However, there is one big "but." The fact is that the efficiency of GTE depends on its power output. GTE of small power (less than 700 kW) have a 1.5 - 2 times more fuel consumption (for 1 kW of power) compared to reciprocating engines. The fact is that in the low-power (and therefore small size) GTE is extremely difficult (or even impossible) to make a high pressure (over 25 bar) by the gas-dynamic method in small size. High pressure in flowing combustion chambers of GTE is needed for to ensure a high degree of expansion of the working gas in order to obtain a good efficiency for small fuel consumption.

The result of the foregoing is that the needs of general aviation can not fully satisfy either piston engines (they are too heavy, bulky and weak ) or gas turbine engines (they are too expensive and have a huge fuel consumption). I.e. general aviation does not have engines for meeting their necessities now.

Thus, we can summarize that the long overdue need for an effective solution to the problem of creating a modern engine for the modern land transport and for general aviation as well as for small vessels. The ideology of the practical establishment of such an innovative engines can be formulated very simply: the design of a new type engine must to combine the positive qualities of all known types of engines (piston, rotary piston, turbine, etc.) and eliminate theirs specific drawbacks.

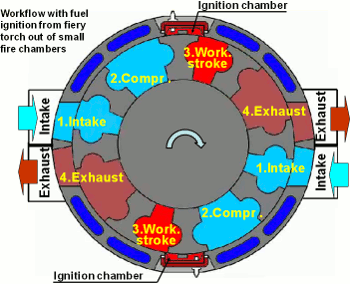

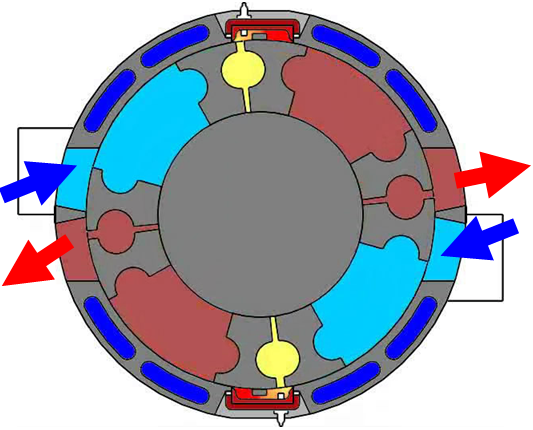

The great thing is that this concept in full, without any exceptions or reservations for the past few years come into life from starting of the scientific and theoretical research, patenting and design of specific engines. This is a 4-stroke Rotary-Hybrid Engine (RHE) of the type "TurboMotor (TM)". The synthesis of all the best qualities of the known types of ICE reflects the word "hybrid" in its title. In particular, the combustion of fuel in a closed volume provides a great peak pressure (up to 100 bar or more) and a great degree of expansion of hot gas provides a good efficiency (like as piston engines). Ability to work on virtually any type of gaseous and liquid fuels, as well as lean air-fuel mixtures ensures the diversity of application of such rotary engine, as well as cost-effectiveness and environmental safety work. In this case, a particular feature of the operating cycle is the constancy of burning fuel in ignition chambers. Particularity of RHE's kinematics is the static equilibrium of the all kinematic elements/parts (like as GTE).

The conception of RHE's kinematics has an international publication PCT № WO 2009/072994 A1 and U.S. Patent № US 8,210,151 B2. Principles of its working process are described in PCT № WO 2011/010978 A1 and the dynamics of these processes are shown below

We are already are developed standard designs for engines with a capacity from 40 up to 420 hp. There is also a design documentation for engines of 40, 80 and 150 hp. There is need a specific customer for industrial implementation of such innovative engines.

We have developed a simple method for numerical estimation of structural perfection of various combustion engines on the basis of the classical theory of thermodynamic processes:

K = W / S,

where:

K - quantification of ICE structural perfection;

W - the number of movable walls in one constructive working volume;

S - the number of cycles of the workflow.

There are shown on Fig.4 the schemes of different engines and objective, science-based numerical estimation of theirs structural perfection. According to this estimate, "TurboMotor" has a 16-fold advantage over the piston engines. As they say, no comments.

| Piston engine |

Wankel RPE |

Bill Gates OPOC-engine |

«TurboMotor» |

|

|

|

|

|

Kre = 1/4 |

Krpe = 3/4 |

Kopoc = 2/2 = 1 |

Ktm = 16/4 = 4 |

Fig.4. Numerical estimation of structural perfection of various combustion engines.

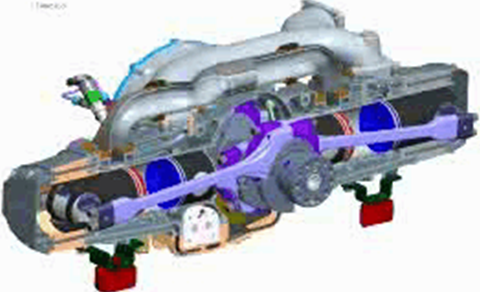

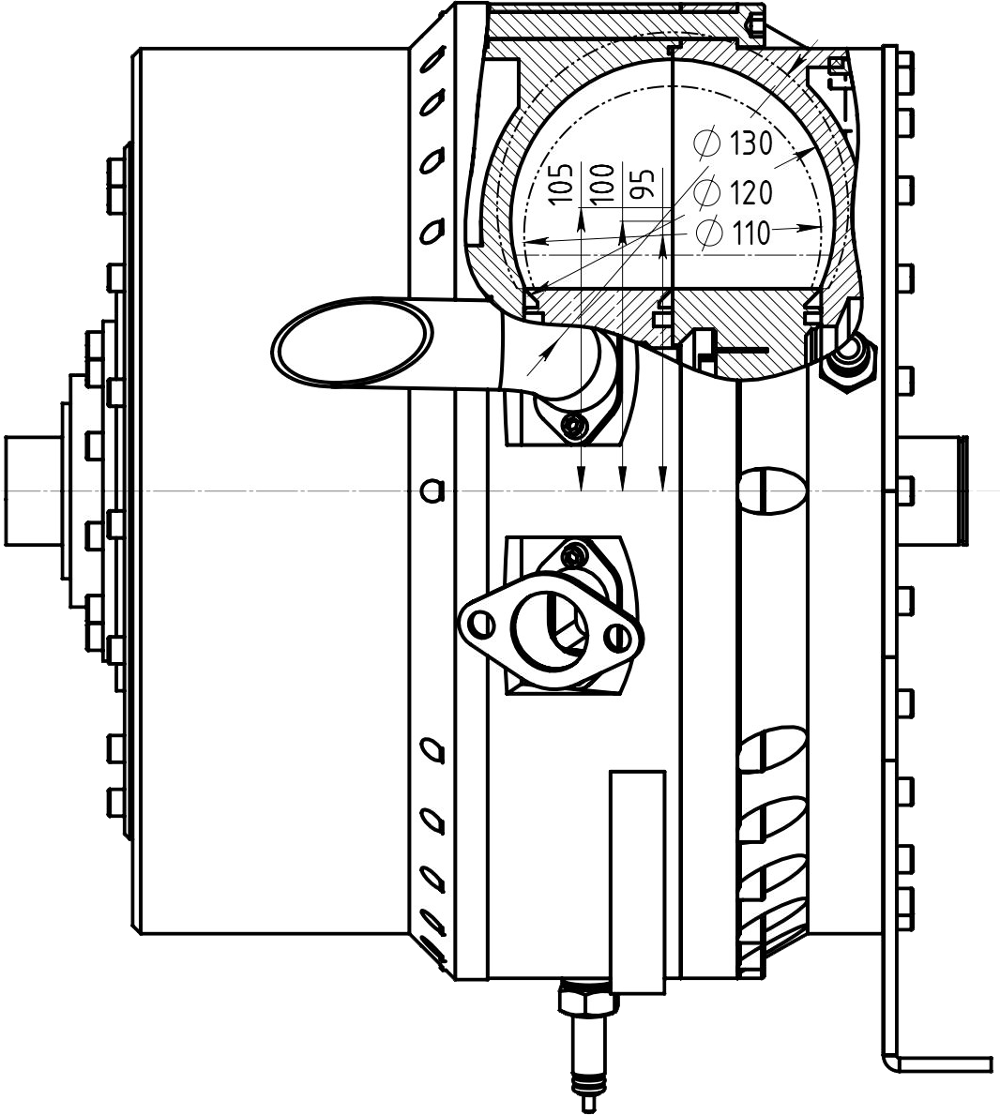

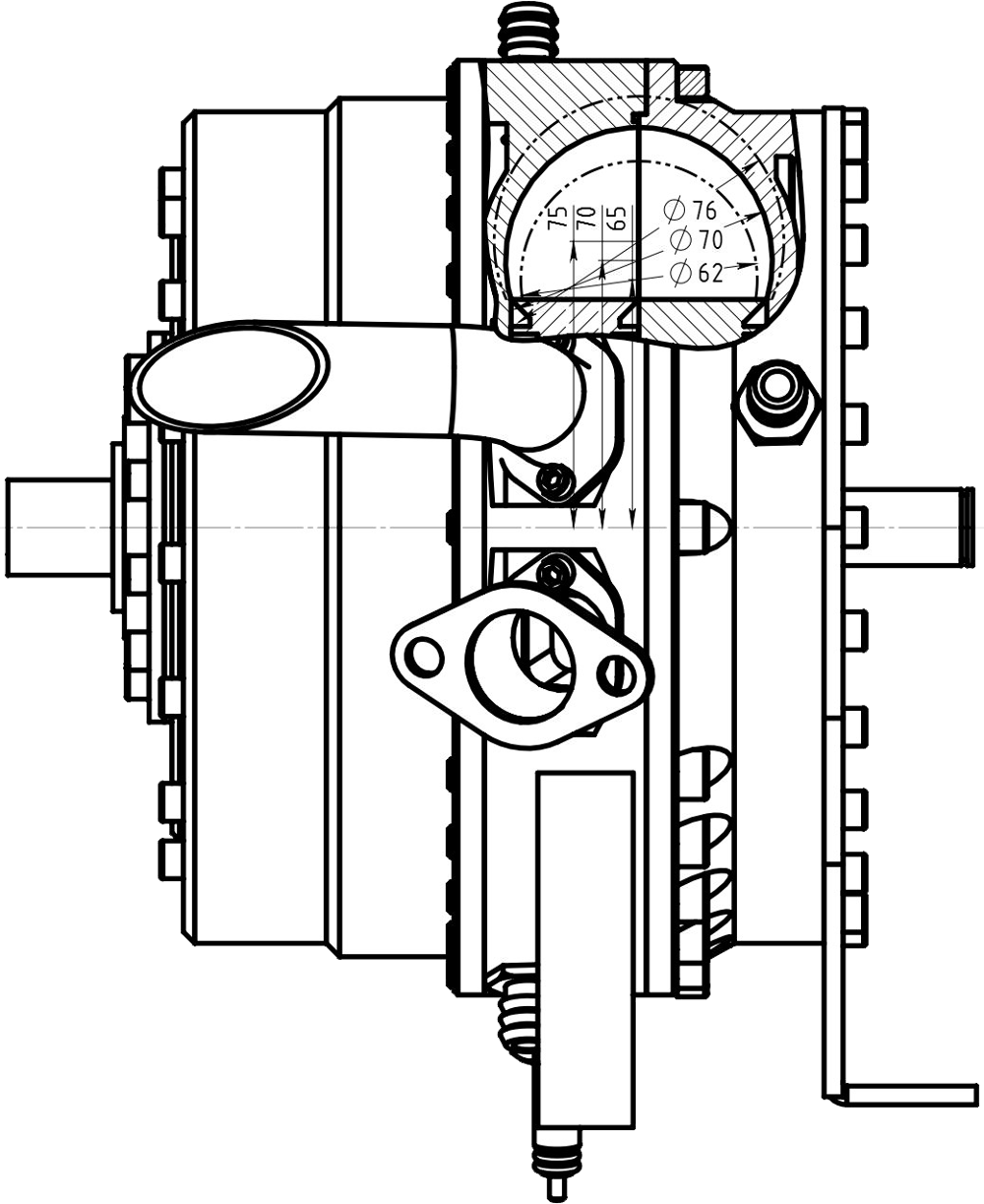

The basic unit of RHE is the kinematic mechanism which works for drive of both rotors which are located in a single engine cavity. The volume of this cavity and thus RHE power depends on its linear dimensions. But we know still at school that the volume of cavity changes in the cubic dependence from its linear dimensions: ΔV = ΔL3. This means that RHE of different power can be implemented on the basis of kinematic mechanisms of standardized sizes only with a slight change in the linear dimensions of RHE's working volume (Fig.5).

|

|

|

|

«A»: 1000 "Turbo+"/420/340/270 hp |

«В»: 200/150/110 hp |

«C»: 80/50/35 hp |

Fig.5. Only 3 sizes of kinematic mechanisms can provide RHE power range from 35 up to 1000 hp (with use of turbocharger).

Fig.5 shows the 3 sizes of "atmospheric" (i.e. non-supercharged) "TurboMotors" which have a design capacity of 35 to 420 hp. It should be noted that their dimensions do not differ significantly in such a big difference as its performance. However, the power of any RHE can be significantly increased (with small or even without any design changes) using turbocharger (similar to the previously described motor "EcoBoost"). There is no necessity to use supercharger for the RHE categories of "C" and "B" because anyway these engines are enough compact and powerful initially. However, application of turbo charging for the RHE of "A"-category is very appropriate for power range extending. Then the power range of only 3 sizes RHE can to reach enormous size - from 35 to 1000 hp! Engines with such capacity will find a very broad applications ranging from household appliances to armored vehicles and aircraft!

Thus it is necessary to take into account the important fact that regardless of the number of rated power of RHE, the number of parts which they contain remains the same as well as the accuracy of their production, which is the main determinant of machine's prices. Accordingly, the labor costs for manufacturing of parts for RHE with different power will be only slightly differing. The difference in the cost of manufacturing RHE of different power will be mainly depending on the amount of materials used.

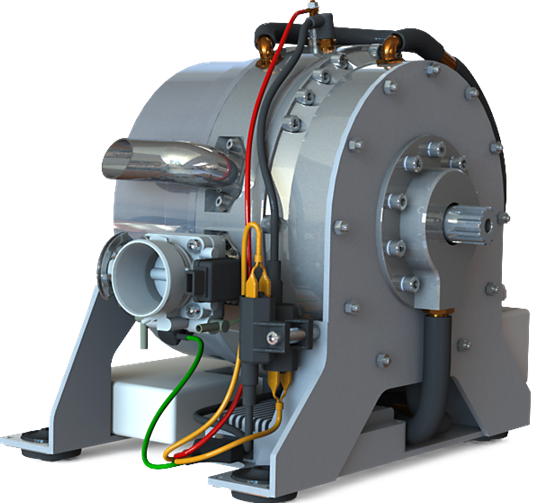

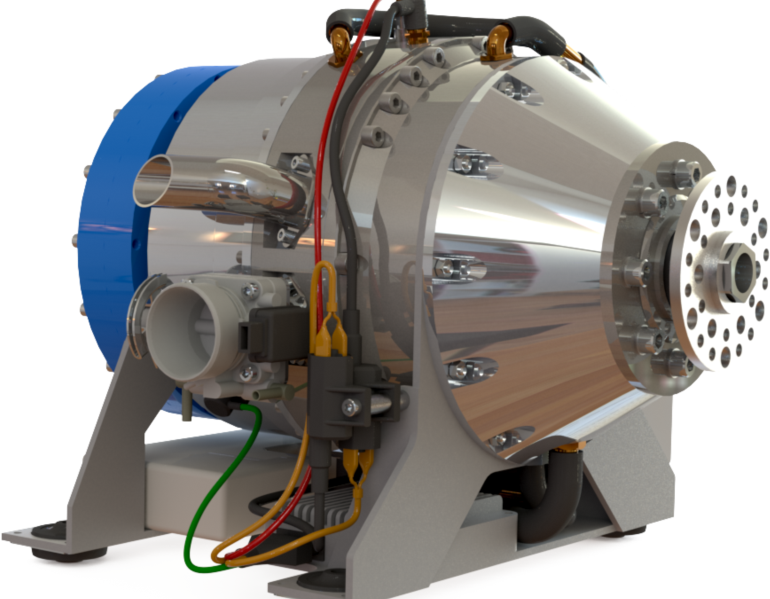

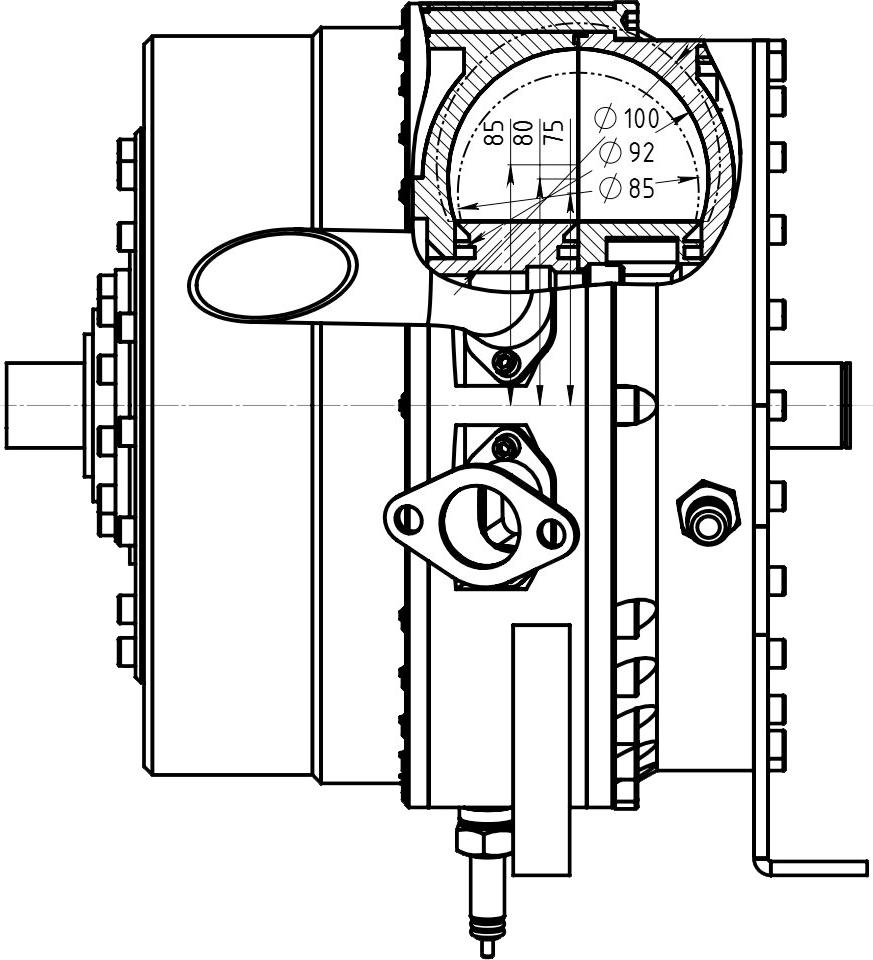

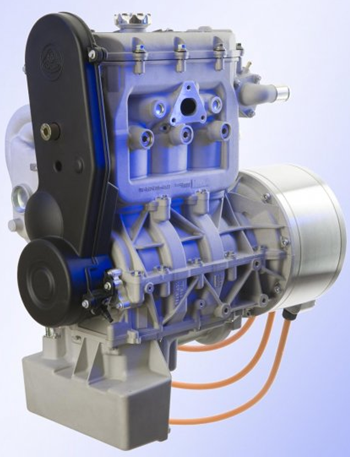

Modern hybrid cars are the natural result of technological progress. However, the synthesis of old-fashioned "reciprocator" with a modern reversible electric machine does not to name a harmonious (see Fig. 6.). Quite differently, as a single whole (see Fig. 7) looks a synthesis of two rotating machines: RHE "TurboMotor" and electric Starter / Generator (blue).

|

|

|

Fig.6. 3-cylinder 1.2-liter hybrid powertrain of "Lotus" electric car , power of 47 hp. |

Fig.7. Rotary-Hybrid Engine "TurboMotor" (power of 70 hp) with a starter / generator (blue). |

It is obvious an exclusive national importance to ensure own industry by the standard engines which are able for consumption of any fuel (RHE are multi-fuel engines) with wide power range (from 35 to 1000 HP) and which are cost-effective and eco-friendly. Quick and huge economic impact will be received not only in the production of rotary engines as well as from reducing operating costs of the huge range industrial products, which will use new engines (Fig. 8).

4. Innovation and transport for "dual use"

U.S Ministry of Defense is implementing today a program called «DARPA's Transformer TX program».The result of this program should be to create a lightly armored four-seater "flying cars" with vertical takeoff and landing (Fig. 9). These vehicles are for military use and are designed for serial production according to orders of the Ministry of Defense that means only by the taxpayer.

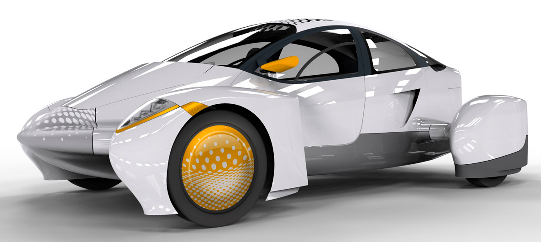

Much more interesting and less expensive, but with a promising nationwide economic effect, in the U.S. by firm "Edison2» (http://www.edison2.com) is developed "Very Light Car (VLC)." The concept of creating VLC laid recognized "green" energy scenario. According to the concept of the company "Edison2" the greatest possible minimization of energy consumption is achieved by weight reduction and aerodynamic losses in order to reduce rolling friction and aerodynamic resistance for movement as a whole (Fig.10). But this is the basic principles of modern aviation. I.e. this is the high road to the creation of efficient "flying car"! And the most impressive in the works by "Edison2" is their practical orientation and achievements. The firm "Edison2" won in 2012 a competition of fuel-efficient cars in the U.S. It was awarded by the prestigious premium «X-Prize» with a prize pool of $ 5 million. VLC's technologies of "Edison2" company can and should be the basis for future "flying cars" to the public using and, if necessary, for special applications.

5. National aspect of the "quadro-technology"

The term "quadro-technology" means 4 times the possibilities of cutting-edge vehicles. This is a double utilitarian function - use of supercars on the public roads and as aircraft, and another double-social function - the use according to decisions of government in emergency situations (for example, search and rescue or disaster management) as well as military purposes (for equipping of national Guards). Total: "2x2 = 4." Such vehicles can be called "Quadro-car" or abbreviated "4-car".

Creation of innovative vehicles for the mass using with double utilitarian functions - use on public roads as a car and as an aircraft - is extremely difficult and complex scientific, technical, economic and social problem. However, the result of its practical solution would have far-reaching social and economic consequences. For this reason this huge problem has to be solved with the participation of government agencies and not just in private. Further we only bring out some aspects of this complex problem basically by theirs listing and the ways of their possible solutions.

- Scientific and technical problem of creation as such "4-car" is regarded by us as the practical implementation for industrial assimilation of a large set of innovative technologies: new materials, functional coatings, technology for processing of constructive materials, etc. Separate private enterprises difficult to solve all complex technical problems only at their own expense and of short time. Therefore, several companies with the financial support of the Government/Governments will have to join forces with companies that already have a practical progress in this direction like the firms "TechResource-Motors" and "Edison2".

- A peculiar scientific and technical challenge is the organization of the movement "4-cars", especially in the air. In our understanding, the movement "4-cars" on the roads will be carried out according to the standard "Rules of the road." However, theirs take-off, flight and landing must be strictly regulated by special rules. First of all, the take-off and landing should be done only from special runways which are divided into four sectors: the preparation and expectations take-off; startup sector; landing sector, sector for aircraft transfer in a traffic state. The procedure itself of flying the "4-car" includes four phases:

-

Entrance into the sector for flight preparation and transferring of "4-car" in flight condition with subsequent inquiry for flight. Simultaneously with a resolution of departure, the "Mission Control" automatically downloads into board computer of "4-car" a flight mission.

-

The "4-car" take-off is realized in manual mode from the startup sector. Immediately after the start should be immediately switch to autopilot with fully automatic control over the entire route. There are constantly duplicated control of the "4-car" route by radars and satellites (e.g. GPS-like system). Any deviation from the route is regarded as an emergency situation that involves the subsequent administrative investigation.

-

Landing is carried out automatically into landing sector with followed by manual control in the transition to the 4th sector.

-

The "4-car" is translated into a transport vehicle condition in the 4th sector with followed by immediate leaving of the landing ground. Power of modern computers able provides a fully automated solution of management of large numbers of aircraft in the air in real time. A practical solution to the problem of the aircraft flight control over populated areas are now researching together several universities in the EU in the framework of the project "myCopter" ( http://mycopter.eu ).

- The most challenging, in our view, is a purely economic problem of decision the accessibility of "4-cars", i.e. their cost of purchase and exploitation should be for no more than the prestigious modern cars for owner. This means that the demand for the "4-cars" should be popular and their production should be a large-scale. Much of this problem is facilitated because is supposed rigging of "4-cars" the mass produced and cheap (due to the high degree of standardization) RHE "TurboMotors" of varying capacity. However, significant contribution to the solution of this problem has made the regulatory policy of the Government in the acquisition of "4-cars" for private use. Such policies may be similar to that which is now used by the U.S. government for the stimulation sale of hybrid vehicles (see below).

- It is well known that most of the surface of our planet is covered by water. People mostly settled along the shores of oceans, seas, rivers and lakes. For this reason there is a need to create not just a "flying car", one must give it a possibility of long term location on the water (swimming) and a normal operation in a hot climate with hot and rarefied air, for example, in the United Arab Emirates. This is an extremely complex task, which can be solved in the framework of "4-cars." Due to its extreme complexity and high cost, but with a great scientific, technical and economic perspective, it can be isolated in a separate scientific and technical direction under the name "Car for Sheikh" (Fig.11, 12).

|

|

|

Fig.11. A dream come true - vast expanses and sea. |

Fig.12. Hither - only with "4-car". |

- Nation-wide significance of the "4-car" is that the transport industry is the engine of the economy of developed countries and its innovative products are the main constituent of export. Stiff export competition calls for industrial implementation of innovations at the earliest. Naturally, it is simpler for government to stimulate market demand in own country and then later expand the export of its products abroad. The U.S. government already has experience in promoting sales of hybrid cars. It can and should be extended and expanded to the "4-cars" in view of their broad functionality for domestic, special and military applications. The last two applications can be made by the government's decision, even if "4-cars" are privately owned.

Conclusion

The car has long ceased to be a luxury. Moreover, it has become a big problem of large cities, which must be addressed. But how? Roads at all are clearly not enough, especially in the rapidly expanding megapolises.

The creation of the Wright brothers gave wings to humanity. However, the modern aviation is a very expensive affair. Economic feasibility makes us grouped in tens and even hundreds of passengers for the air flight. And only a very few of us have the luxury of flying with a friend or alone. The reason for this is simple - the high cost of flight prevents using of aircraft in the daily life. This situation is a result of its technical and economic imperfections, first of all of basic components - the currently existing engines. In particular, piston engines are heavy, bulky and weak, and the gas turbines (with a capacity of up to 800 HP) are too expensive and have huge fuel consumption.

The solution to expand the mobile capabilities of modern man may be the creation of the mass car "Quadro-use": for daily land/air/water using and special application ("2x2"). Theirs basis may be the development of "Very Light Car (VLC)" of firm "Edison2" (USA) which can be equipped with low-cost, compact and lightweight, economical and environmental safety Rotary Hybrid Engine (RHE) of type "TurboMotor" with the participation of the company "TechResource-Motors "(Ukraine). We invite all interested parties together for contribute to the development of the transport industry and impart way to vehicles in the sky.

Naturally, such an ambitious and socially important project should be implemented with the direct participation of state agencies to accelerate the economic development of the country and provide a national security. We understand that the most important part of the government's work is full justification for decisions. This article can be considered as the primary information for the formation of some state programs of national importance.